Encapsulated O-Rings

Encapsulated O-ring is a two-component circular seal consisting of Teflon encapsulation and elastomer (Silicone / Viton). Encapsulated in a Teflon jacket, it is a chemically resistant seal used to prevent passage of corrosive fluids or gases. This encapsulation protects the elastomer, which imparts memory to the seal, from hostile environments.

Encapsulation Options

- FEP Encapsulation

FEP encapsulation which is a standard material for all applications. It can resist up to 205°C and virtually all chemicals. A joined by an advanced heat moulding process to give a seamless encapsulation. - PFA Encapsulation

PFA encapsulation which has the same properties as FEP encapsulation,however with greater heat resistance for applications above 205°C. It resists to virtually all chemicals and joined seamlessly via advanced heat moulding process.

Characteristics of Encapsulated O-Rings:

- Corrosion Resistant

- Low absorption

- Uniform dimensions

- Non-flammable

- Excellent Resilience

- Enclosed Core

- Reusable

- Live Seal

- Abrasion Resistant

- Permeability

- Chemically Inert

- Impact Strength

- Smooth surfaces

- No Swelling

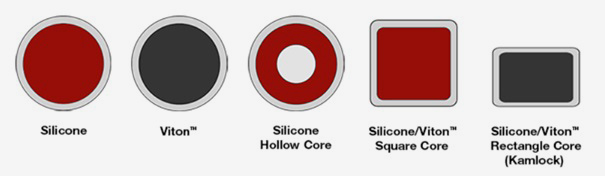

Ring Shape Options

- Non-standard ring shapes (e.g. square, rectangular, oval) are possible on request to suit specific application requirements.